Quality control division

Lab-Service is strongly involved in the management of the quality system. The company wishes to maintain a high level of quality and is constantly looking for areas for improvement. We want to guarantee our customers a quality system management.

Lab-Service scrupulously follows the GMP and it’s:

- inspected by ANSM

- inspected by FDA (US)

- approved by Japanese authorities

- controlled by the veterinary services for the food industry, DPP (Direction Protection des Populations)

Quality Assurance is responsible for :

- control and sustainability of the quality system

- quality documentation management

- batch release

- qualifications and validations

- conducting and following up customer, external (suppliers) and internal audits

- staff training

For any product processed on our site, a complete batch file is established. The batch file is controlled by Production then MANDATORY released by Quality Assurance. No product may leave our site without being released by QA (except upon written request by the customer).

Audits and Inspections

Our company is regularly inspected by the authorities (FDA, ANSM) and audited by our customers. On average, 2 to 3 customer audits are carried out each month on our site. For each inspection or audit, we systematically write and send an action plan following the remarks that could be made. The various actions are monitored during the quality meetings held regularly between the various department managers.

Qualified suppliers

We work with different suppliers (drums, PE bags, equipment maintenance, solvents, etc.) to ensure continuity of service. Critical suppliers are strictly selected, qualified and monitored by Quality Assurance. Regular audits are performed at our critical suppliers to verify GMP compliance. Each new critical supplier must be qualified and approved by Quality Assurance, which includes it on the list of approved suppliers.

Staff training

All staff are trained and qualified. Quality Assurance manages staff clearance and records each training course in the employees’ file. All employees are frequently trained (GMP training, new procedures, customer complaints, etc.). And this, in order to maintain a high level of quality.

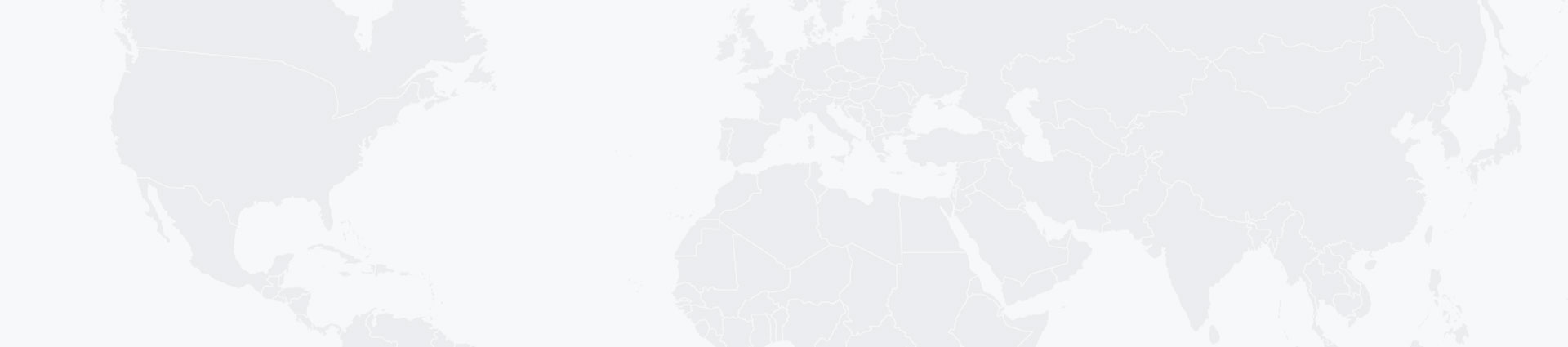

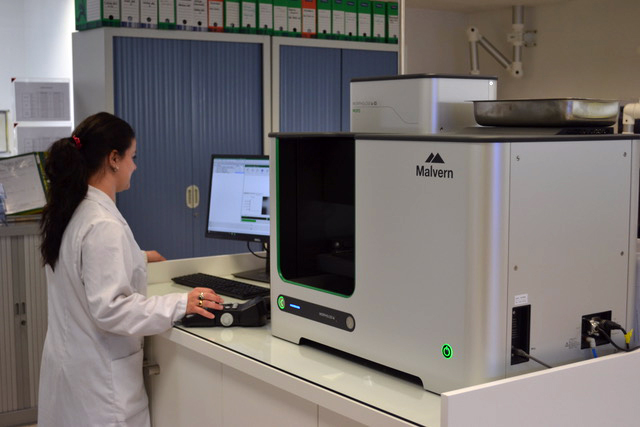

Control laboratory

Our Quality Control Laboratory is composed of trained personnel and qualified equipment.

The Control Laboratory is responsible for:

● granulometric analysis of raw materials, CPIs (quality control) and finished products

● powder characterization by particle size distribution determination

● the validation and visual control of cleaning of production rooms

● cleaning validation on worst-case products

● adjustment of micronization parameters for obtaining powder sizes in customer specifications

● validation of granulometric analysis methods and validation of micronization and grinding processes

● air quality control in the production room by particle counting and microbiological sampling

● the control of raw materials by IR spectrometry

The Laboratory possesses 5 granulometers:

● 1 Beckman Coulter Multisizer IV ® meter

● 1 BECKMAN ® Coulter LS13320 laser particle size analyzer

● 3 MALVERN ® Mastersizer 3000 laser particle size analyzer with one only dedicated to ß-lactams

● 1 MALVERN ® Mastersizer 3000+ laser particle size analyzer

● 1 HPLC for cleaning validations

● 1 Zetasizer Ultra-red

● 1 UV spectrophotometer for cleaning validations

● 2 IR spectrometers for the identification of raw materials and finished products with one only dedicated to ß-lactams

● 1 Morpho G4 for morphological particle analysis

● Optical microscopes for editing microscopic pictures